Vibrating Wire Piezometer: Precision in Groundwater Measurement

A piezometer is an instrument used to measure the pressure within a fluid, commonly groundwater, at a specific depth or point. It is crucial in groundwater monitoring and soil pressure measurement, providing essential data for geotechnical engineering, hydrology, and environmental science. This article explores how piezometers, particularly vibrating wire piezometers, operate and their unique benefits and applications.

Understanding Piezometers and Their Importance

The Basics of Piezometer Technology

Piezometers come in various types, each suited to specific applications and environments. These include pneumatic, hydraulic, and vibrating wire piezometers.

The choice of piezometer impacts the accuracy and reliability of the data collected, making it crucial for professionals in fields like geotechnical engineering to understand their distinctions.

Piezometers are pivotal in projects that require monitoring of soil moisture, groundwater levels, and the structural health of engineered structures such as dams, levees, and tunnels. They help engineers and scientists make informed decisions based on precise measurements of underground water pressures.

Leading brands in the industry include Schlumberger, Geokon, RST Instruments, Campbell Scientific, and Durham Geo Slope Indicator (DGSI).

How Does a Vibrating Wire Piezometer Work?

Components and Functionality

How does a piezometer work? The vibrating wire piezometer is distinguished by its method of measuring pressure via the tension of a wire. This piezometer consists of a diaphragm with a wire stretched across it, connected at both ends to an anchor in the instrument’s body. When groundwater pressure is exerted onto the diaphragm, it causes the wire to vibrate. The frequency of these vibrations is directly proportional to the pressure exerted.

Thanks to the vibrating wire piezometer’s design and operation, as pressure varies, so does the tension in the wire. This alters the frequency of its vibrations. The piezometer’s electronic components then measure and convert these frequencies into electrical signals, which can be read and recorded to provide accurate and continuous groundwater pressure measurements.

Advantages of Vibrating Wire Technology

Accuracy, Reliability, and Longevity

Vibrating wire piezometer benefits include superior long-term stability and reliability in diverse environmental conditions. They are particularly valued for their ability to remain accurate under variable temperatures and pressures, which often affect other types of sensors.

The technology’s robustness makes it ideal for critical applications where precise monitoring of pressure changes is necessary for the safety and maintenance of structures. Additionally, the longevity of vibrating wire piezometers reduces the need for frequent replacements and maintenance checks, providing a cost-effective solution for long-term projects.

Applications in Geotechnical Engineering

Real-World Use Cases

Vibrating wire piezometers are used in water level monitoring for large-scale infrastructure projects. For example, in dam monitoring, these instruments provide vital data that helps assess the dam’s structural integrity and safety. They are also used in mining to monitor the stability of tailings dams and in urban development projects to determine the groundwater and soil mechanics and conditions before construction begins.

Vibrating wire piezometers’ versatility makes them suitable for a range of other applications, including landslide prediction, environmental restoration, and research studies aimed at understanding aquifer dynamics and soil contamination. Accurate stress measurement in soil, for example, is crucial for assessing the stability of slopes and embankments.

Installation and Maintenance Guide

Step-by-Step Process

The installation of a vibrating wire piezometer is a critical process that requires careful planning and execution to ensure accurate data collection and minimal disruption to the surrounding environment.

Here’s a step-by-step piezometer installation guide:

- Site Selection and Preparation: Before drilling begins, select a site that is representative of the area you wish to monitor. Ensure that the site is accessible for equipment and personnel, and clear any debris or obstructions.

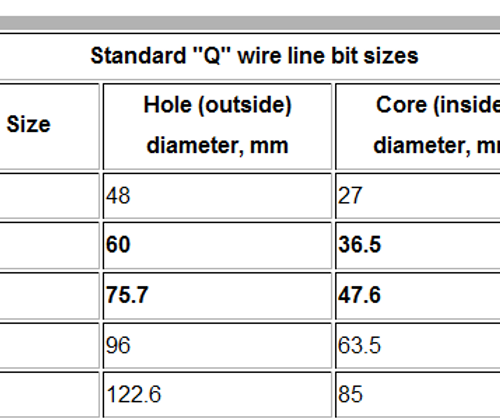

- Drilling the Borehole: Using appropriate drilling equipment, bore a hole to the desired depth where the piezometer will be installed. The depth and diameter of the borehole depend on the geological conditions and the specific requirements of the monitoring project.

- Preparing the Piezometer for Installation: Before placing the piezometer into the borehole, make sure that it is properly calibrated and all components, such as cables and sensors, are securely attached and functioning.

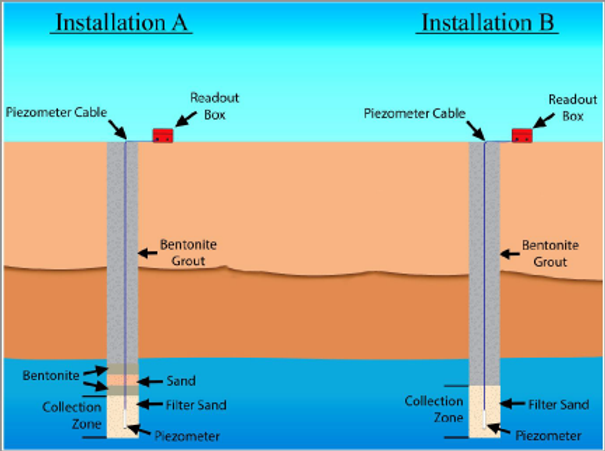

- Placing the Piezometer: Carefully lower the piezometer into the borehole, ensuring it remains vertical and reaches the bottom of the hole.

- Backfilling the Borehole: Once the piezometer is in place, backfill the borehole with a suitable material to ensure good contact between the piezometer and the surrounding soil. Sand or a fine-grained bentonite/cement mixture is often used for backfilling, as it provides an effective hydraulic seal and minimises disturbance to the soil’s natural state.

- Connecting to a Readout or Data Logger: Connect the piezometer to a readout or data logging device. This device will record the data transmitted by the piezometer.

- Verification and Calibration: Once the piezometer is connected, perform a series of tests to verify that it is operating correctly and recalibrate if necessary.

Best Practices and Common Troubleshooting Tips

After installation, regular monitoring and maintenance of the piezometer and its connections are necessary to ensure continued accurate functioning. Schedule regular checks to verify system integrity, recalibrate the instruments as needed, and check for signs of wear or damage.

Common issues might include signal loss due to cable damage or errors in frequency reading due to electronic malfunctions. Regular checks can mitigate these issues, ensuring the piezometer functions as expected.

For more information about our exploration drilling services, get in touch with us today on 0425 479 150 or mathew@precisiondrillingaustralia.com.au.

FAQs

1. What is the principle behind vibrating wire piezometer technology?

Vibrating wire piezometer technology measures groundwater pressure through the tension changes in a wire stretched across a diaphragm, altering its vibration frequency.

2. How is a vibrating wire piezometer installed and maintained?

Installation involves drilling a borehole, placing and backfilling around the piezometer, and connecting it to data logging equipment. Maintenance requires regular calibration and checks for electrical integrity.

3. What are the key benefits of using a vibrating wire piezometer over traditional types?

Key benefits include higher accuracy, stability over time, reduced susceptibility to environmental influences, and continuous, real-time data monitoring capabilities.

4. How can the data from a vibrating wire piezometer be interpreted?

Groundwater monitoring with piezometers shows changes in water levels and pressure over time. Data is interpreted using software or conversion charts that translate vibration frequencies into pressure readings.