Deep drilling refers to the process of drilling deep boreholes into the earth’s subsurface to explore, evaluate, and extract valuable resources or assess geological conditions.

There are several methods of deep drilling, each with its own advantages and suited to different applications:

Air Drilling

Air drilling comprises three primary shallow drilling techniques: air-core, reverse circulation, and rotary air blast. These methods typically employ a utility, track, or small truck-mounted rig with an onboard or towed air compressor.

Air drilling generates rock chips by forcing compressed air down the drill hole, lifting the chips to the surface. This drilling method is efficient and minimally invasive, requiring little site preparation and rehabilitation.

Diamond Drilling

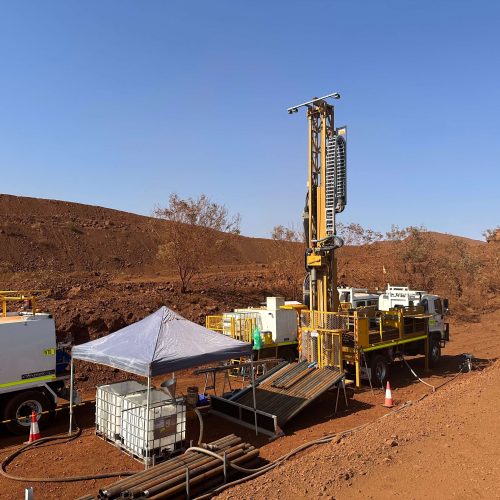

Diamond drilling uses a truck-mounted or track rig with support vehicles to extract a continuous cylinder of rock. The method involves water and drilling fluids, which are either stored in an in-ground sump or above-ground tanks.

Diamond drilling demands significant site preparation and rehabilitation, but it provides accurate and continuous core samples. It is commonly used in combination with reverse circulation drilling for mineral and coal exploration drilling.

Rotary Mud Drilling

Rotary mud drilling is predominantly used for petroleum and deep stratigraphic drilling. This method generates fine rock fragments and uses water and drilling fluids to lubricate the drill bit and return the rock fragments to the surface. The drilling fluids are contained in either in-ground sumps or above-ground tanks.

Rotary mud drilling rigs are generally larger than those used for other methods, requiring more support vehicles and site preparation. This technique is ideal for exploration drilling oil and gas, and other valuable resources.